Grand Rapids, MI 49512

FORNAX Motorized Vinyl (PVC) Hot Liquid Profile Bending Machine

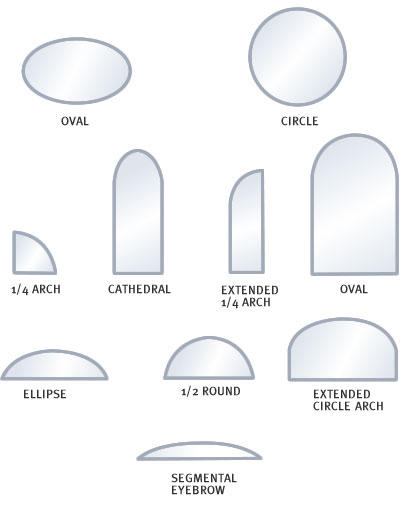

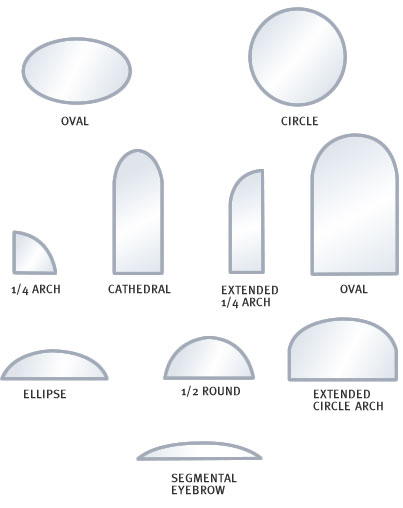

The FORNAX motorized vinyl (PVC) profile-bending machine is designed to bend vinyl profiles including the side lengthening. The machine may also be used to form arches or shapes.

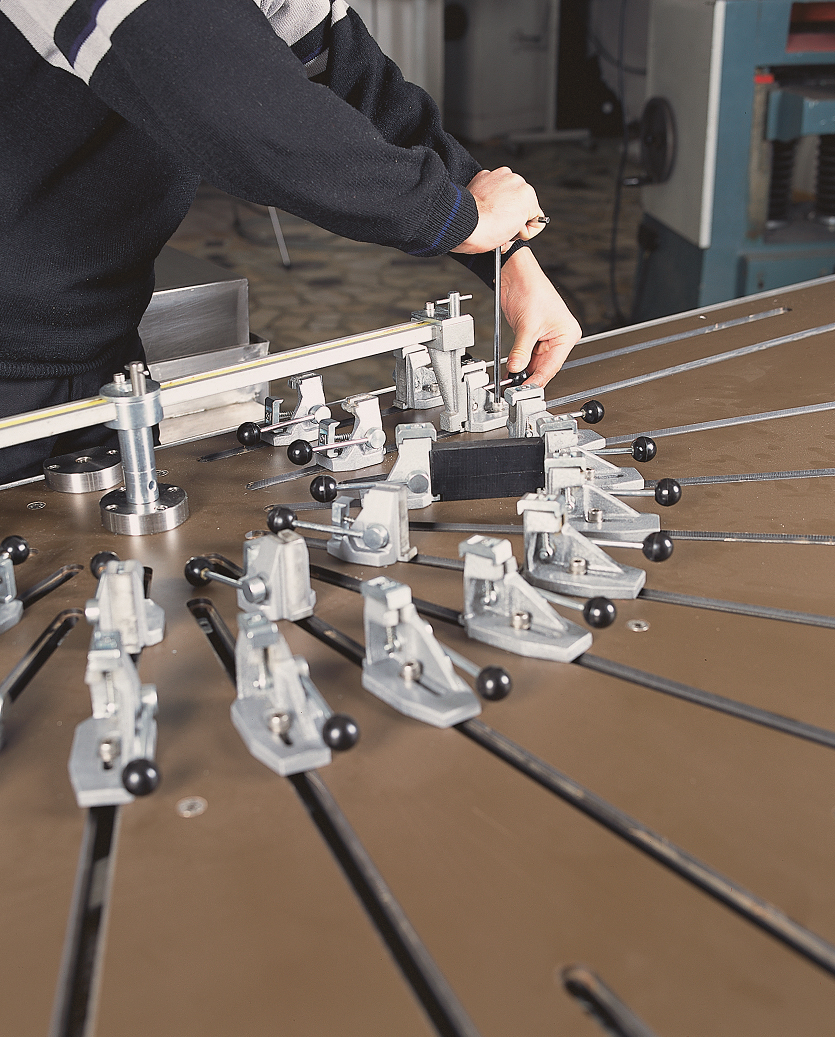

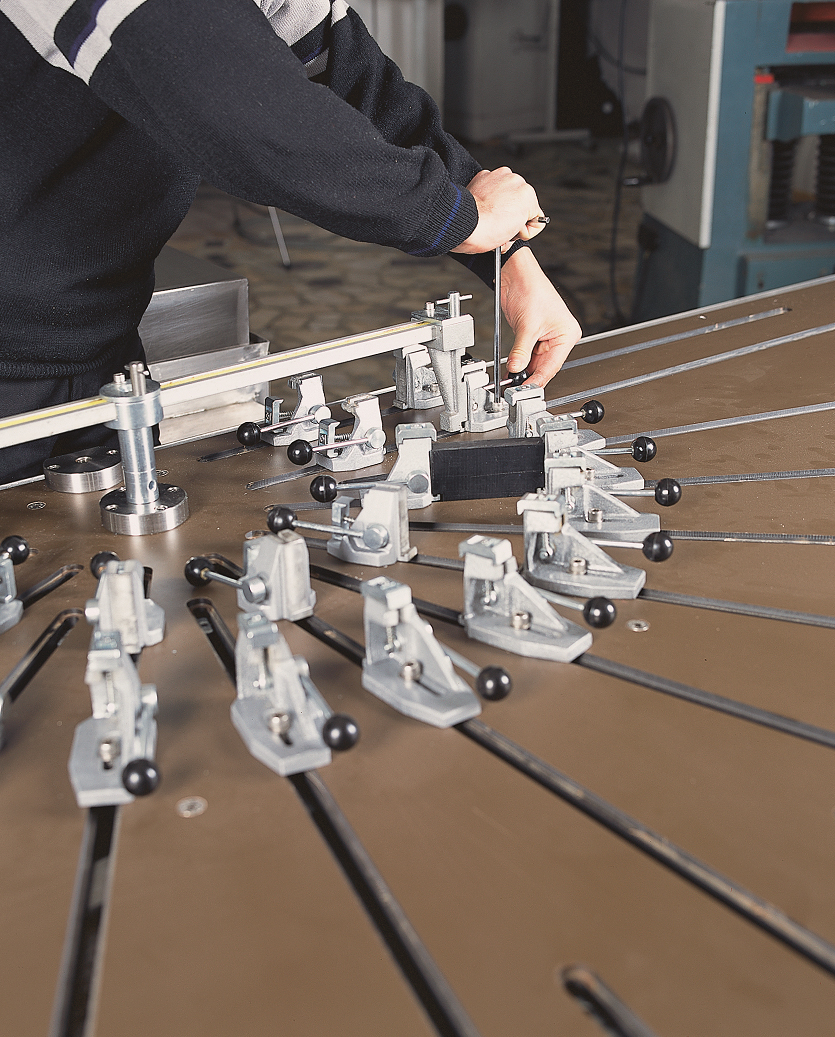

1-Work Bench

2-Side Lengthening, which may be separated from the machine

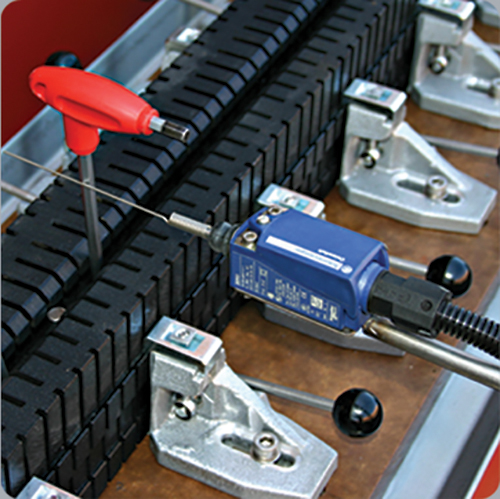

3-Bending Moulds, Interior Spades, Distance Gauges

4-A Pull Bench where the Motor is tightened

5-Heater

6-Compass

7-Traction Apparatus

8-Central Compass Lightening

9-Immersion Gravities, which immerses the profiles into oil

10-Draining Tanks

11-Washing Tank

12-Front Trestle Bracket

13-Rear Trestle Bracket

Dimensions: 25 x 1259 x 2800 mm (1″ x 50″ x 110″), height 830 mm (33″)

15 exterior and 15 interior mould holder aluminum square sets are inserted into the T-channels on the work bench to support the bending moulds. The bending moulds may be fixed to a desired diameter by using the compasses. The top spandrel may move to the left or the right approximately 400 mm (16″) with the aid of a gear without moving the work bench.

The side lengthening may be used to bend arches. The dimensions of the mould holder aluminum square sets assemble placket are 300 x 1600 mm (12″ x 63″). The numbers of the internal and external mould holders are 28. To achieve the desirable arch diameter, the side lengthening of the machine may be moved to the right and the left parallel to the working bench with the aid of a gear shaft. To do a bending by using a stencil or without using the side lengthening, a comfortable level is needed for adjusting the distance to the machine.

The bending moulds and distance gauges are 3000 mm (118″) and 2500 mm (98″) in length, i.e. 5500 mm (217″) in total. The interior padding are manufactured 3000 mm (118″) and 4000 mm (157″) in length. The materials of the interior padding and bending moulds are heat-resistant, flexible and slippery. The internal paddings are designed to avoid deformation while working with profiles with narrow diameters. Distance gauge aluminum mould holders may bend glass bars without adjustment.

The pull bench is manufactured from profile pipes and may be used to pull the profile into the moulds and to pull out the internal padding out of the profile. The motor is 2-rptated and carries a brake for applying immediate stop. The wheels beneath the main frame are easily adjustable and may be taken out or put back on the machine as required.

The heater is made from stainless steel, and has a 2-mm thickness. The 10 kW power allow the heater to supply sufficient temperature for the oil. The temperature control is achieved by digital thermometers and thermostats. It is insulated by a 30 mm thick glass wool, which is covered by stainless steel. This insulation provides a 25% reduction in power use. The steam emission equipment provides the steam coming from the heater, and does not permit its diffusion into the working area. The aspirator may work with a low capacity when the lids are closed. When the lids are opened, it may work at a higher capacity to emit the steam to the exterior environment. The heater has a switch box containing the necessary equipment to operate as needed. The heater level may be adjusted with respect to the workbench. The round rollers in the profile resting pan prevent the heated profiles to rubb on the pan.

The compass is used to adjust the mould bender holders to any desired diameter. It has 2 rulers with 1100 mm (43″) and a 3100 mm (122″) in length.

This apparatus is used to bend arches without the side lengthening. It is also used to pull the heated profiles into the bending moulds.

This may be used as a central lengthener for extra 950 mm (37″).

The gravities are 3 pieces, and they keep the heated profile immersed beneath the surface of the oil. These items are manufactured from stainless steel.

These are used to drain the oil remaining inside the profiles. These are 2 pieces and are manufactured from stainless steel. This oil is discharged back to the heater tank to re-use.

The washing tank is made from stainless with 1.5 mm thickness, and used to wash the bent profiles.

This is used in order to prevent any deterioration of the exterior parts of the bending mould that hangs loosely from the sides of the working bench.

This part may allow the heated profile including its interior padding to be adjusted to the level of work bench.

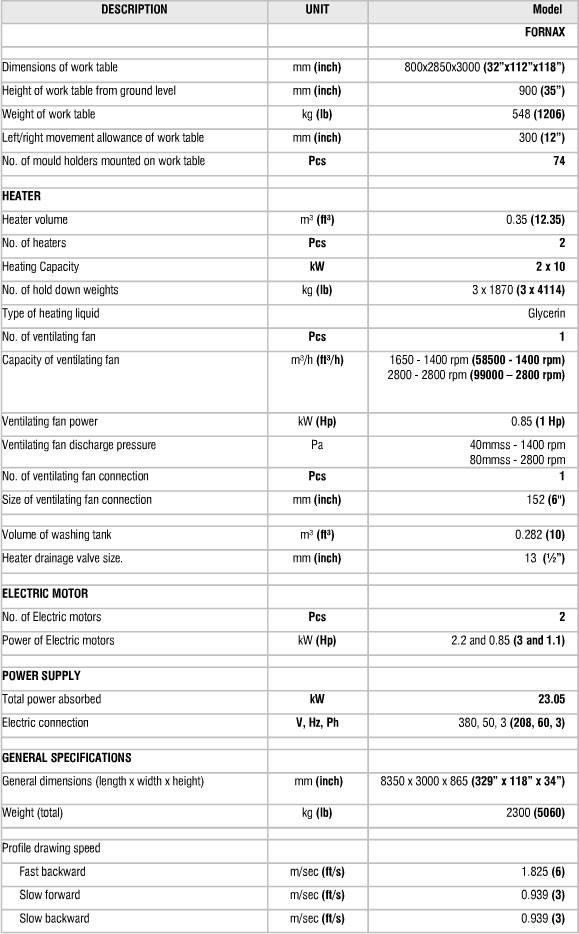

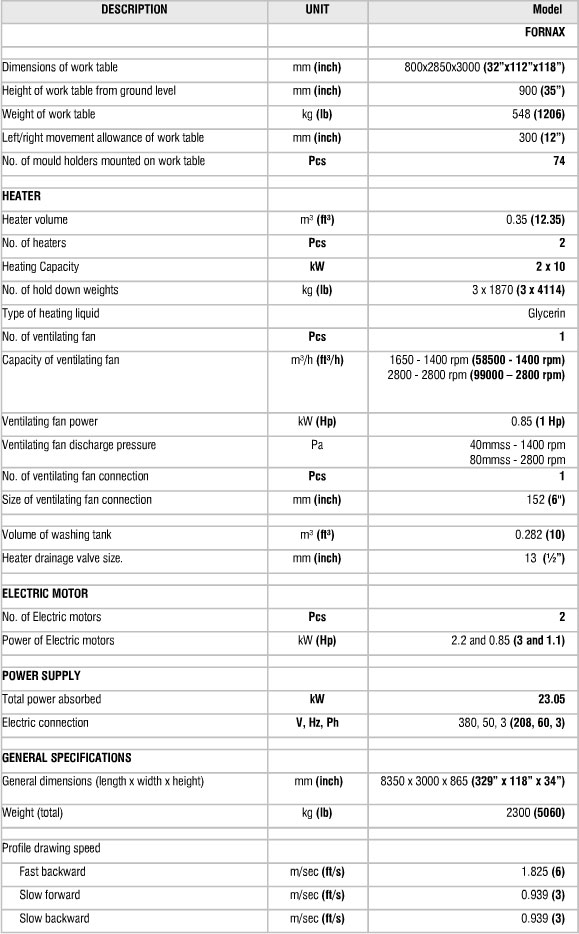

Technical specifications and features are subject to change without prior notice.

User's Manual

User's Manual Catalog

Catalog Video

Video